Flap Control System

The lift coefficient manipulator and energy dissipator.

The Patrol flaps are actuated with a unidirectional cable system, retraction is accomplished by springs and ram air. The flaps are conventional and effectiveness is accomplished by size rather than fowler-style gaps. It’s a simple design with the advantage of having a clean wing in cruise and on the ground (no hinge contraption hanging out).

Fuselage Part

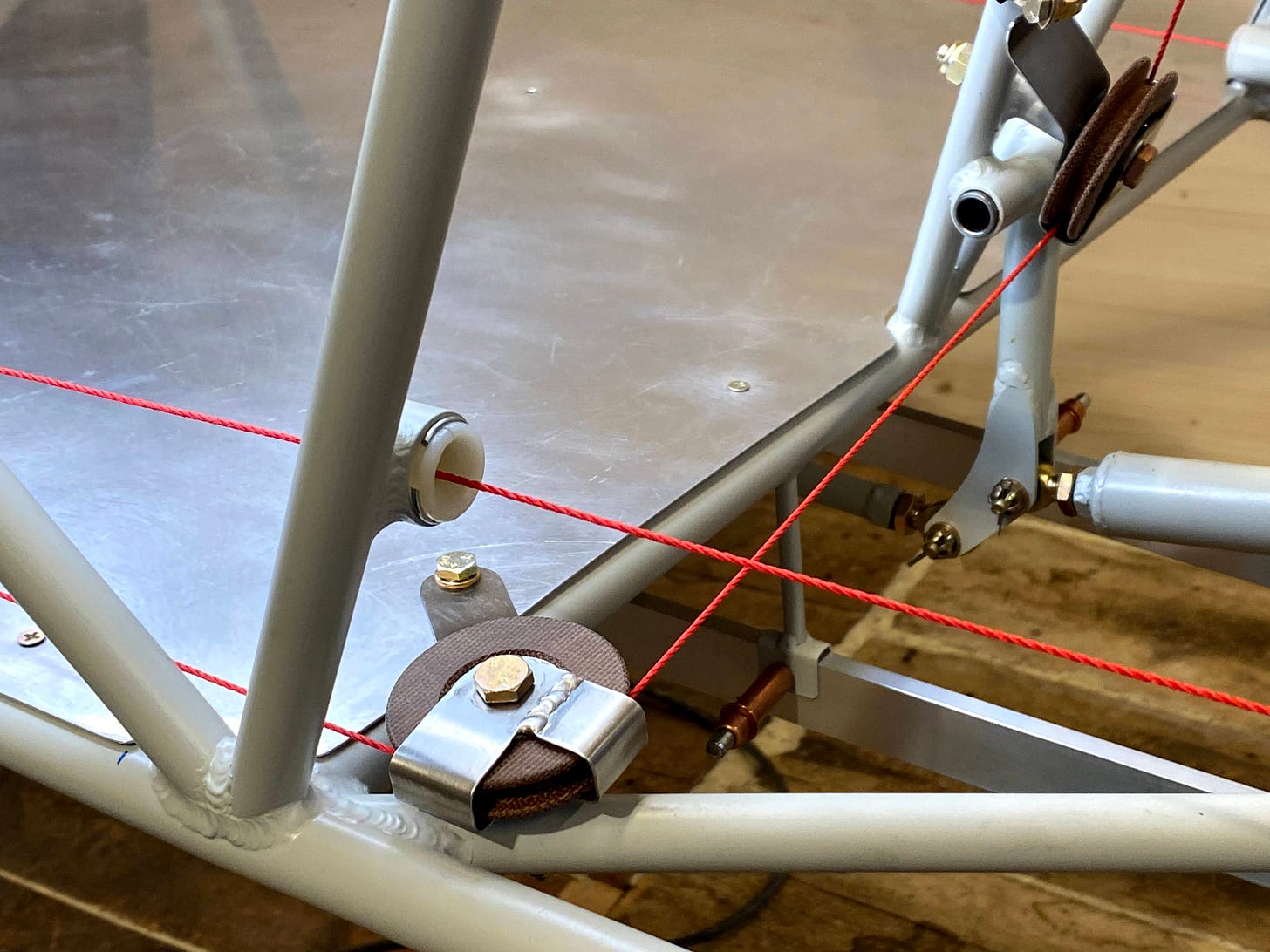

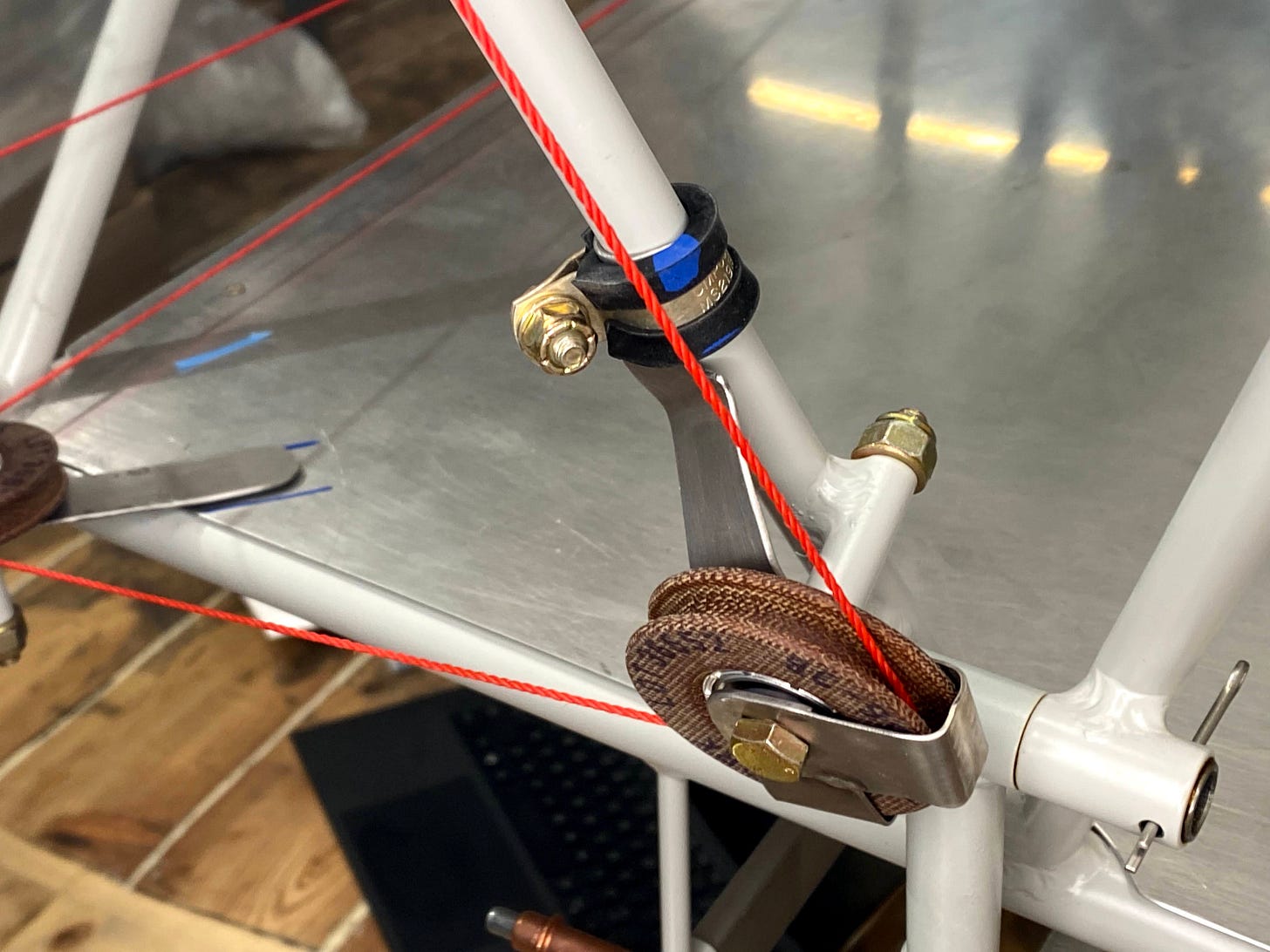

The cable runs from the flap handle to flap pulley 1 just behind the cargo compartment. Pulley 2 is centered behind the cargo bulkhead. Then the cable connects to a triangular junction plate and splits towards pulley 3L and 3R at the top of the fuselage. The junction plate is also the location of the cable tensioners. Pulley 3L and 3R redirect the cable to the front where pulley 4L and 4R deflect it slightly upwards to align it with the flap torque tube lever.

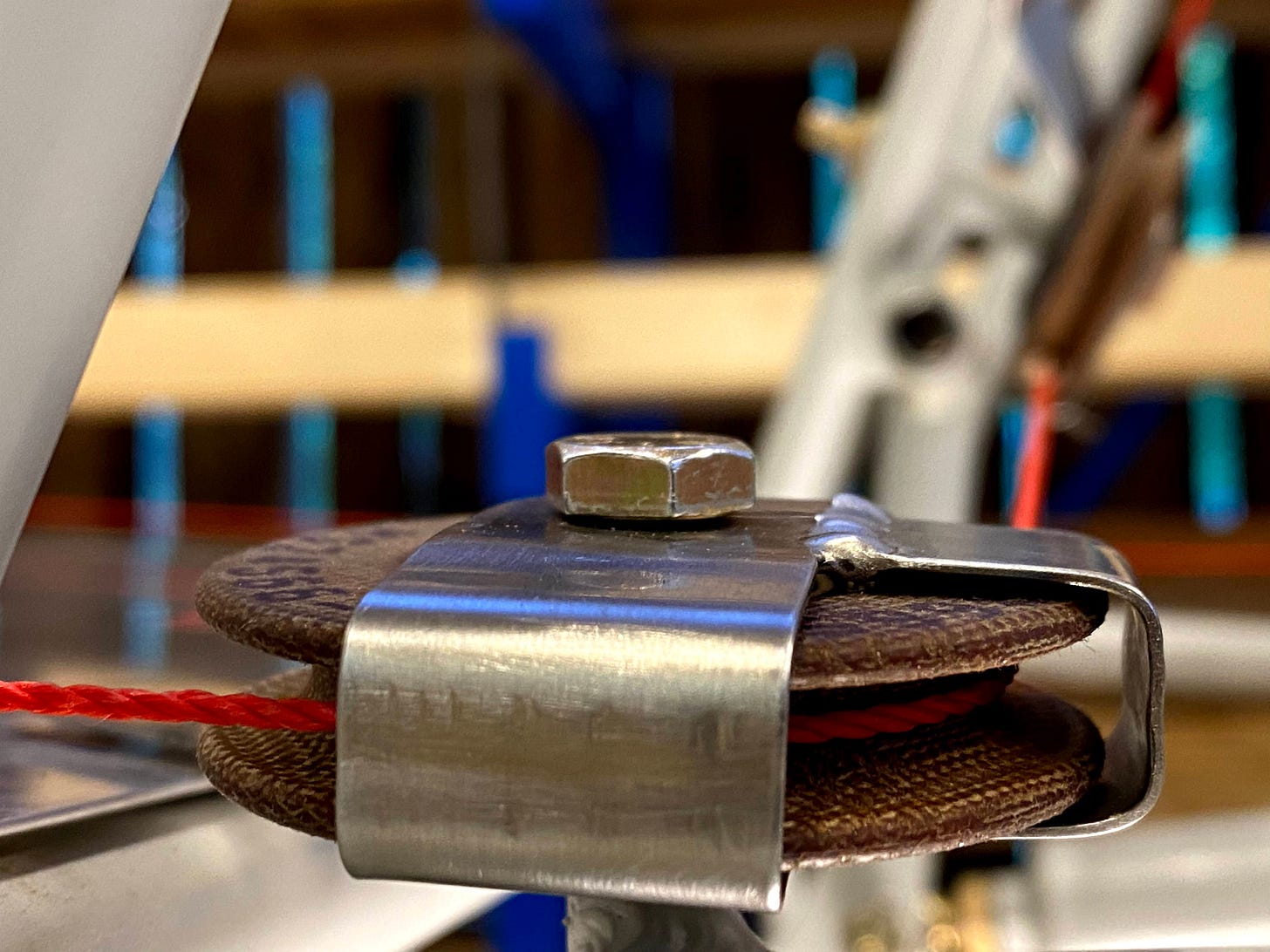

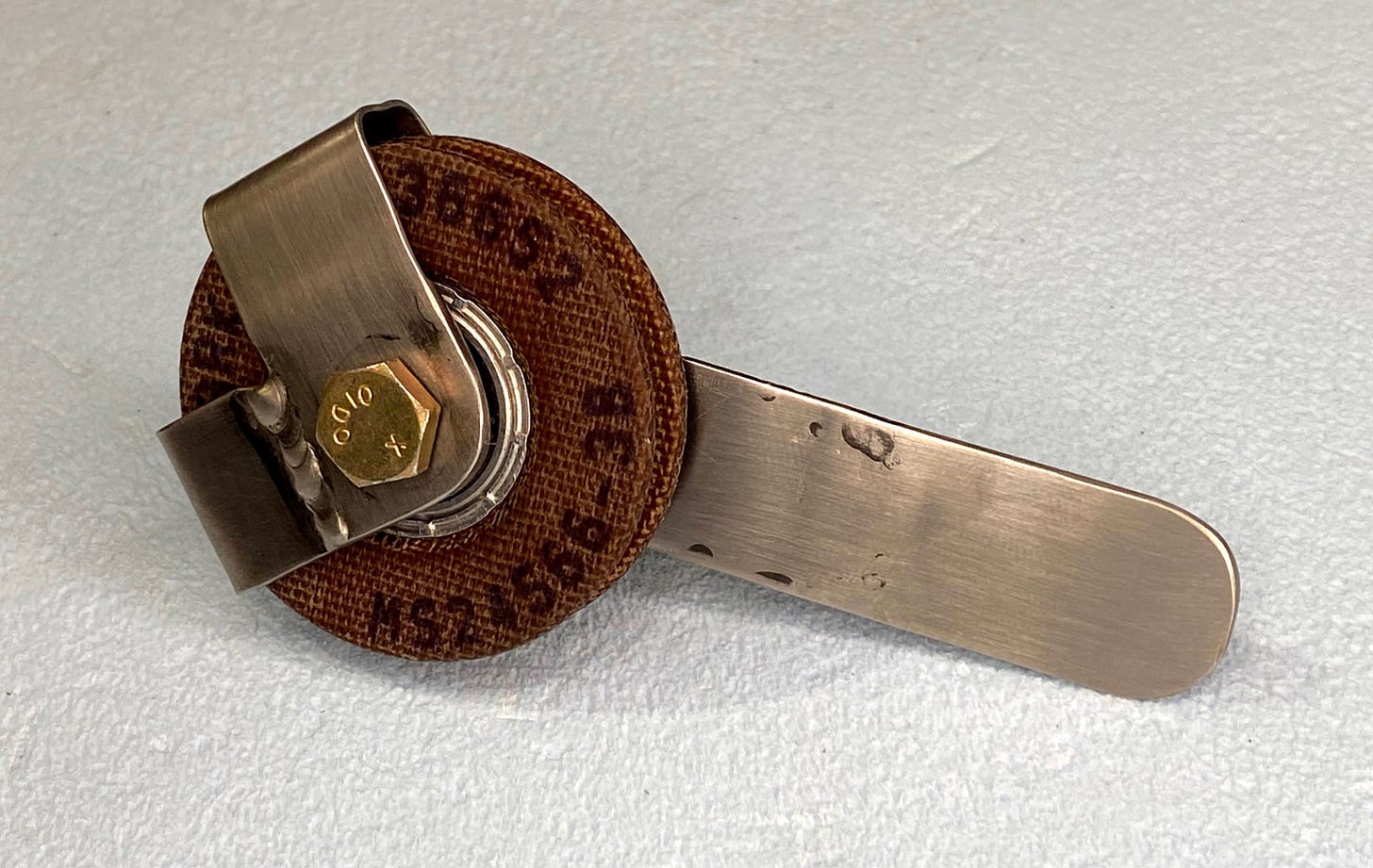

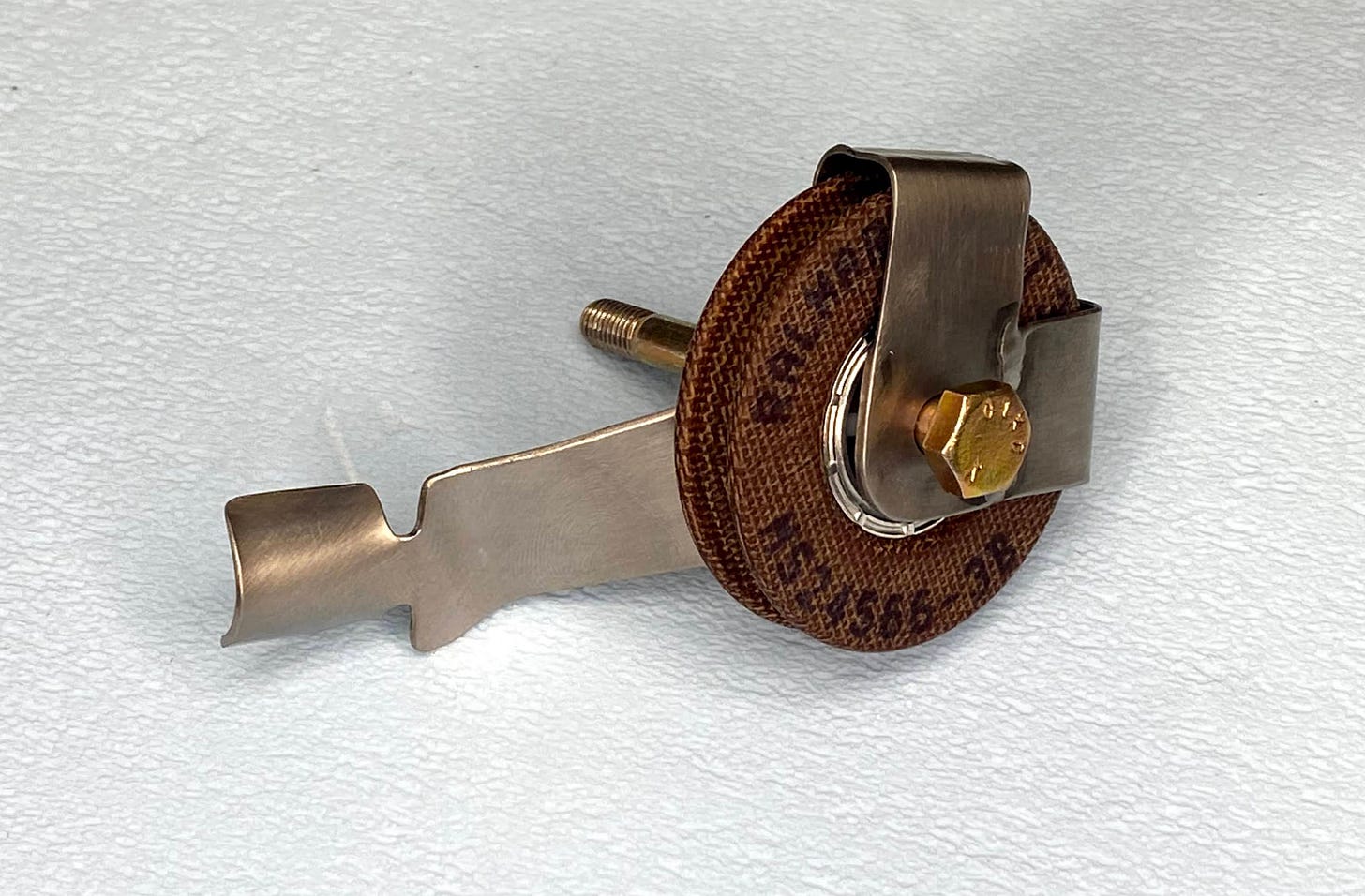

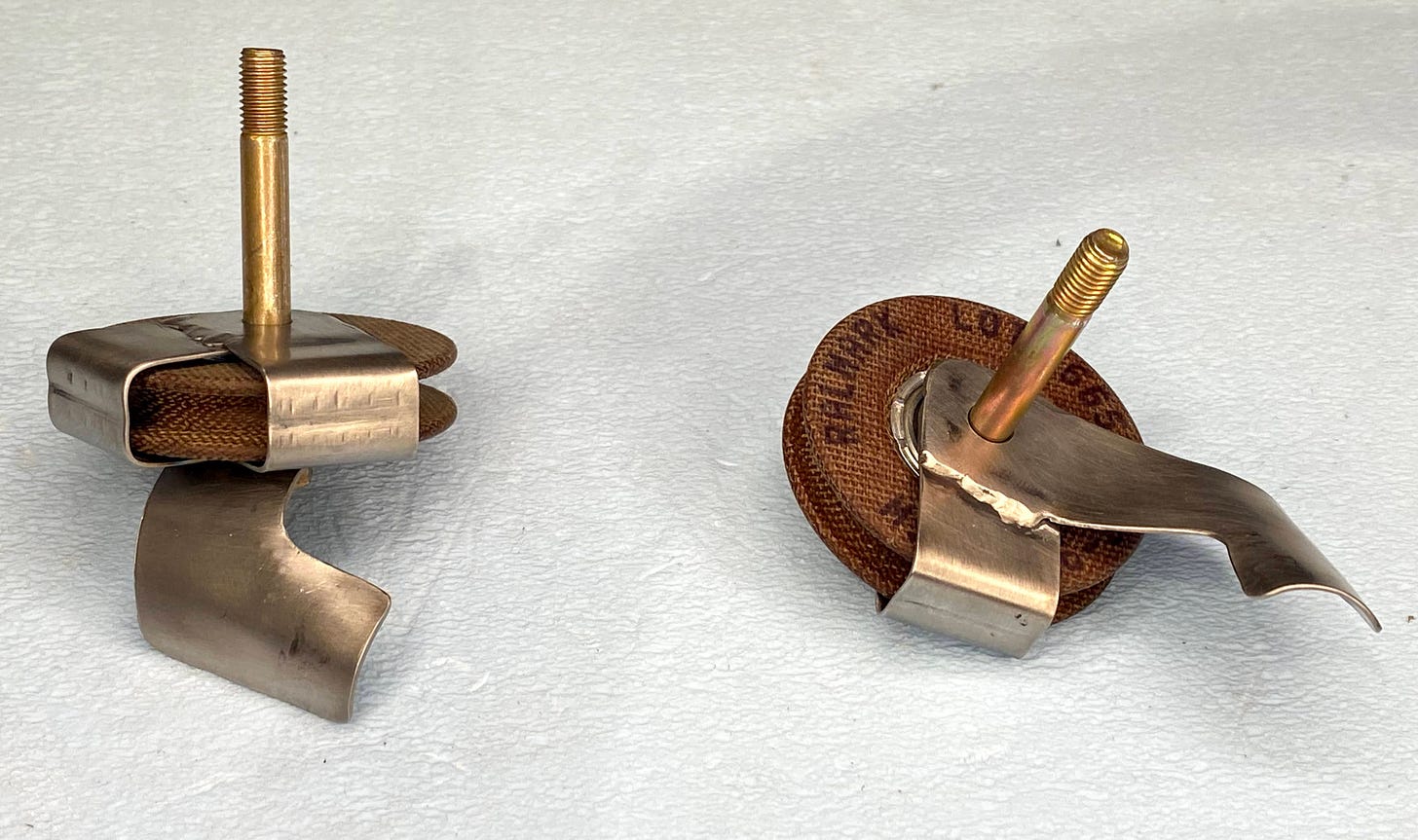

Six pulley guards need to be manufactured to secure the cable. In terms of shape, size, and strength the kit-supplied aileron pulley guards are a good reference. The bends can be accomplished with a wooden forming block. Precision drilling is crucial. A marking caliper and a center drill bit were indispensable. To deburr the insides some unbending and re-bending is necessary. It took me a couple of hours to get the tolerances right. Also some welding is required when building them with proper arresting arms.

In my case I decided to make the arresting arms of pulley guard 1 and 2 structural to also function as reinforcements of the cantilevered mounts. This is my modification to address a non-critical saftey update from July 2021.

For pulley 3L and 3R the proximity to the fuselage is intended to function as guards. Additional guard at the top can be omitted.

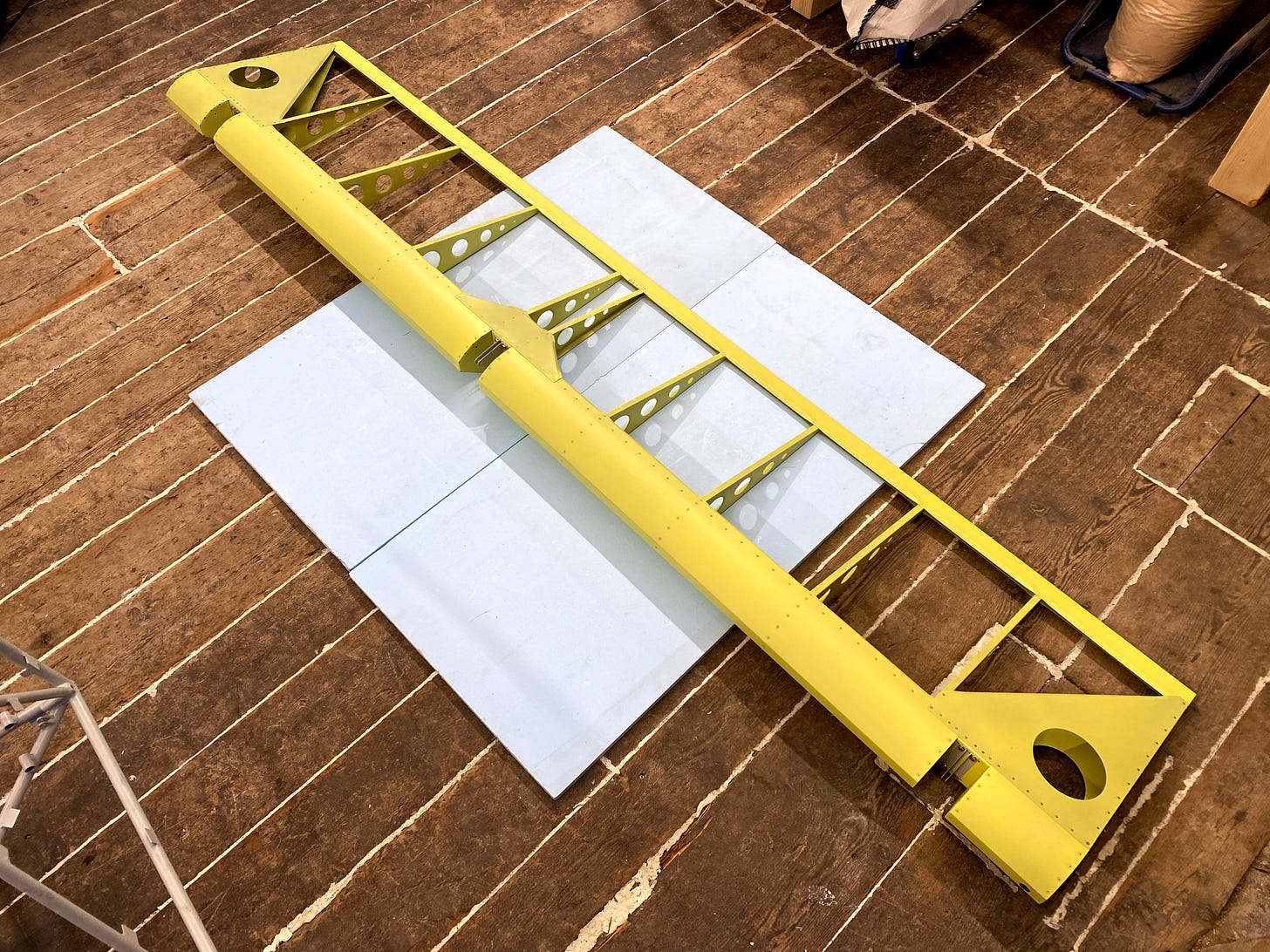

Wing Part

(to be written)