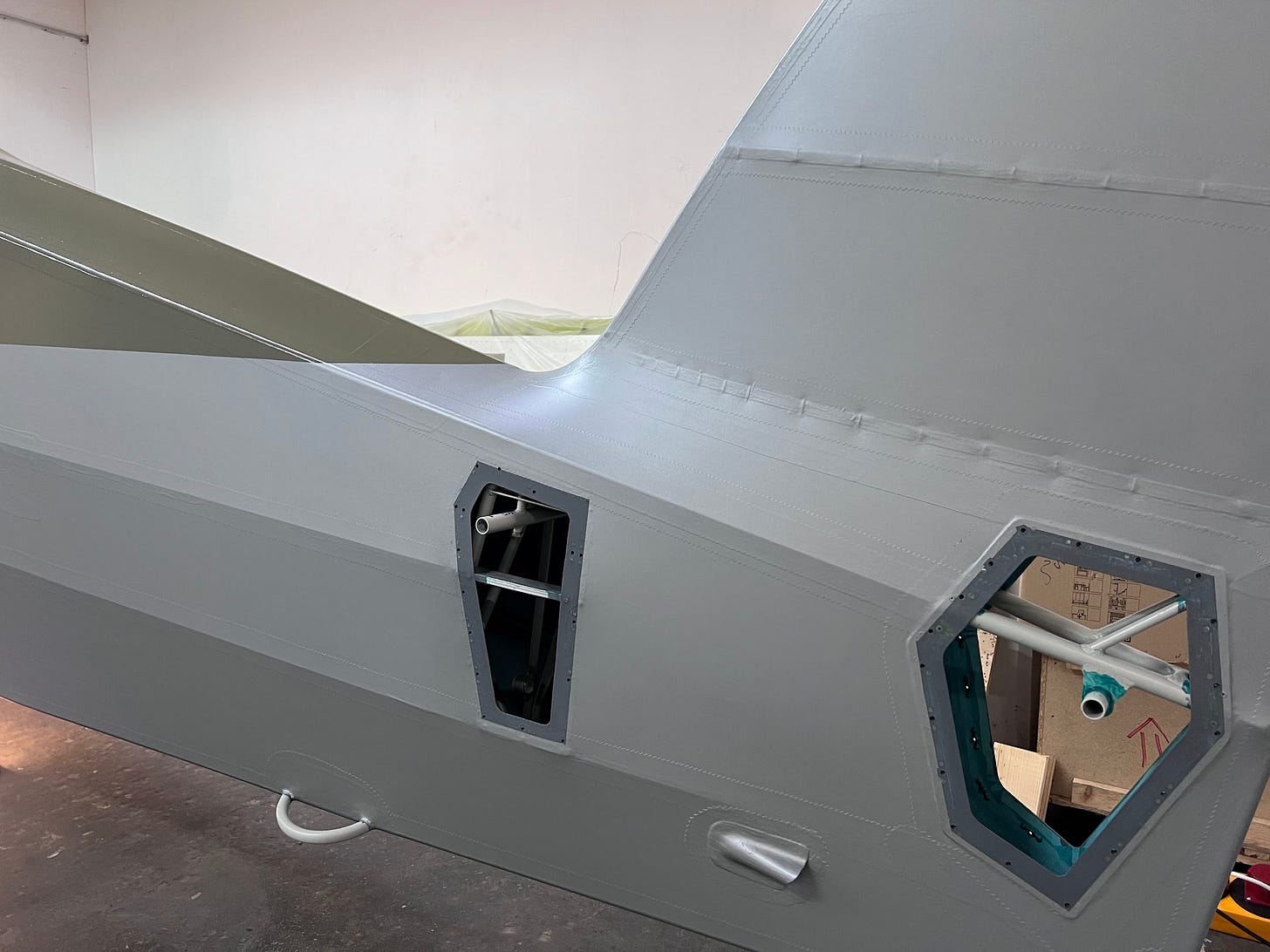

Bearhawks are tube and fabric airplanes. They are build around a strong, oxy-acetylene welded, chromoly space frame fuselage and a lightweight skin. Specifically this means a fabric skin for many surfaces of the airframe. Getting this skin airworthy is what fabric and paint systems are designed to do.

First step is to choose one of these systems. Once you are past the analysis paralysis and all the forum flame wars the rest is a walk in the park. In my opinion the main choices are Polyfiber, Stewart, and Oratex. Polyfiber is for people who like proven systems and don’t mind breathing a lot of MEK. Stewart is great for amateur paint booths as it lacks volatile solvents. Oratex is for everybody who wants to paint as little as possible. Beyond this superficial take, I can refer to the AMT guide to Aircraft Fabric Covering.

Stewart System was my choice after a lot of deliberation. I liked the lack of volatile solvents and found the documentation better than others. Specifically having good docs for dealing with all the various surface materials I found helpful and reassuring. I also do not have difficulty painting within a narrow range of temperature and humidity (15-30℃, 15-75% humidity). The 1-year shelf life is a big downside, and the storage requirement (5-35℃) can be a challenge. This makes it hard to do international shipping in winter. For details refer to the Stewart Manual. Check Stewart website for updates.

Products by Application

The following summarizes what the various products are used for. Some shortcuts and simplifications are possible. Generally the super-easy-to-use EkoPrime (1K) can be used in place of EkoPoxy (2K). Also, the fabric top coat EkoPoly can be used in place of the slightly harder EkoCrylic.

Fabric Covering and Painting

Superflite 102, 2.7oz, 92g/m2 (fuselage, tailfeathers, flaps, ailerons)

Superflite 101, 3.7oz, 126g/m2 (gear legs, lower fuselage, lower horstab, trim tabs)

EkoClean (general cleaning agent)

EkoBond (fabric adhesive)

EkoFill (smoothing and UV protection)

EkoPoly (topcoat, flexible, fabric-optimized)

Aluminum Painting

EkoClean (general cleaning agent)

EkoEtch (aluminum prep)

EkoPoxy (2K primer, exterior, metal, composites)

EkoCrylic (topcoat, harder, metal, composites)

Chromoly Frame Painting

EkoClean (general cleaning agent)

EkoPoxy (2K primer, exterior, metal, composites)

EkoCrylic (topcoat, harder, metal, composites)

Composite Painting

EkoClean (general cleaning agent)

EkoFill (UV protection, if no gelcoat)

EkoPoxy (2K primer, exterior, metal, composites)

EkoCrylic (topcoat, harder, metal, composites)

Paint Equipment Setup

Painting is about controlling many equipment and environmental parameters. This is a different way of saying that many things can go wrong. The Stewart manual goes into great details on this. Many forum entries are about suboptimal results because one or multiple of these parameters are off.

That being said, it’s doable. I got good results on the first try. I also burned a lot of cycles to set everything up and gain a deep understanding. At times I felt like a magician dealing with potions, elixirs, and ancient books. I am not surprised anymore that some people just do paint, as a job. It’s dense.

Air Compressor

Must supply more than 350lpm/6bar (13cfm/90psi) and the

Air filters and hoses (3/8" dia) need to allow for enough air flow (see instructions)

Use a high quality water-trap/regulator and a good .01micron filter

My filter setup:

Limit hose length to 15m (50') and regulator to air gun to 10m (30').

Setup procedure:

Use water in the paint gun to test the system.

Start with fan control all the way open, fluid control mostly open.

Adjust compressor to 8.5 bar (125 psi)

Adjust regulator to 5 bar (75 psi).

Adjust gun to 1.2-1.4 bar (18-20 psi) when pressed.

Adjust air control valve on the gun to manufacturer recommendations.

Keep spraying and check if the pressure on the gun stays constant when the compressor cycles on/off.

➜ starting with 7 bar (comp), 4 bar (festo reg), 19 psi (gun 3M)

Paint Gun

The Stewart manual recommends various paint guns. My weapon of choice was the 3M AccuSpray with PPS 2.0 cups. It makes it very easy to have a clean gun every time and eliminate contamination issues. I also found it easy to source.

3M AccuSpray Gun 26778, PPS 2.0

200µm cups ➜ EkoFill, EkoPrime, EkoPoxy

125µm cups ➜ EkoPoly, EkoCrylic

1.6mm nozzle (violett) ➜ EkoPoxy

1.3mm nozzle (green) ➜ EkoFill, EkoPrime, EkoPoly, EkoCrylic

Procedures

General Covering Sequence

Clean, scruff (scotch brite), clean

Apply anti-chafe tape

Cover the structure, one side at a time with overlaps (1" overlap, 2" finishing tape)

Initial shrink at 120℃ (250℉, in two directions, 6 in/s)

Apply all reinforcement patches

Intermediate shrink at 150℃ (300℉, in two directions, 6in/s, only iron to the edge of patches)

Final shrink at 180℃ (350℉, 3x, some light smoke normal)

Apply rib reinforcement tape (where applicable)

Rib-stitching with hidden, modified Seine knot (where applicable)

Apply rib finishing tapes (where applicable)

Apply edge finishing tapes

Install service openings (do not cut open until needed)

Iron down all tape edges

Make drain holes (solder-iron-burn small holes at the lowest points)

Clean with EkoClean (diluted 15:1, spray, lint-free cloth, make sure silicone-free)

Rinse with water (use sponge), let dry

Seal with diluted EkoBond (3:1, 1 being water, foam brush, no wiping, vid)

Inspect wing, iron down edges, fix bubbles

➜ Paint Fabric (start with EkoFill, vid)

Note: This is not a good point to store the parts because of the tacky nature of the EkoBond. Apply at least one cross coat of EkoFill before putting the parts on hold. This first cross coat can be applied by foam brush if the spray booth is not quite ready to go.

Fabric Painting Sequence

Spray 3 cross coats of EkoFill (one session)

fog cross coat (2 coats), perimeter first

➜ second part of cross coat as soon as dull looking

After each cross coat (wait 45min) ➜ dry sand dull, wipe&blow clean

Sand off all the microfuss of the pinked edges

Use Scotch Brite around sensitive areas like rib stitching

Iron down (110°C) pinked edges, iron out defects like bubbles

➜ don't sand through filler coat

Wait about a day but no more than 10 days (after last sanding)

Spray 4 coats of EkoPoly (one session, this is for a matte finish)

Tack coat

Wait until tacky (5-10min)

4 fog coats, ~28cm distance (let get tacky in between 5-10min)

for a shiny finish the last coat would be a wet coat at ~16cm distance after fog coat is tacky)

Note: Masking tape is best removed after the last top coat. This prevents a ridge from forming. Also, small runs under the masking tape can sometimes be fixed by simply wiping off the excess paint.

Surface Cleaning

The surface needs to be scuffed, dry, oil-free, and dust-free before painting. This typically requires the following steps:

clean (paper, IPA or EkoClean)

scuff (320 grit or red Scotch-Brite)

blow & wipe (tack-wipes)

clean (lint-free rag, IPA)

Surface Treatment

Steel surfaces need to be clean, oil-free (isopropyl), and primed (EkoPrime or EkoPoxy) before being topcoated (EkoCrylic or EkoPoly). Light rust can be removed with scotch brite, heavy rust with a sand blaster.

Aluminum surfaces need to be cleaned (EkoClean then rinsed), scuffed (scotch brite) and simultaneously etched (EkoEtch, must not dry, rinsed), and primed (EkoPrime or EkoPoxy) before topcoated (EkoCrylic or EkoPoly, fully dry but within 12h of etching).

Composite surfaces need to be cleaned (first with lacquer thinner then with EkoClean), scuffed (320 grit abrasive), filler-primed (EkoFill, also UV protection, if no gelcoat), then primed (EkoPrime, EkoPoxy), before topcoated (EkoCrylic or EkoPoly).

Fabric surfaces (superflite) are applied with EkoBond, filler-primed (EkoFill), primed (EkoPrime if white substrate to bright colors is required), before topcoated (EkoPoly). Weight of 1 square foot of fully finished fabric is 0.8oz (244g/m2).

Rib Lacing

Start with square knot with a half hitch on each side

At each tie point make a hidden modified seine knot

Distance between tie points is 50-63mm for the Bearhawk

Starting/end point is 38mm from the edge

EkoEtch

EkoEtch (aluminum prep)

2:1 diluted with water (1:1 for corroded AL)

Wear eye protection, gloves

Spray up to 1m2 and scruff with scotch brite (3min)

Rinse, before it dries, remove all residue!

Test with lint-free rag, wipe with IPA ➜ if black too much residue ➜ re-etch

Low dry any rivet lines with compressed air

Let dry for 1h, prime within 12h

Paint with EkoPoxy (or EkoPrime)

EkoBond

EkoBond (fabric adhesive)

Gluing fabric to structure

Brush on undiluted (5% water can be added)

Can be applied directly onto bare AL

Scuff and clean on narrow structure to improve adhesion

Use 1" brush

Let it dry so it becomes tacky

Press fabric into it, use iron at 100°C to "glue clamp"

When positioned, iron fabric into bed layer at 135°C

Fabric to fabric joints

1" overlap is approved

Min 2" finishing tape over joints

(wing trailing edges must have 2" overlap with 3" finishing tape)

Always iron glue joint at 135°C

Brush from top, wipe off excess!

Apply to seal fabric - Stewart Video

Clean fabric with EkoClean diluted 15:1 ➜ spray bottle

Spray, wipe with lint-free rag

Rinse with distilled water and sponge

Make sure to wash out a fresh sponge, remove all the chemicals

Let dry 2-3 hours

Foam brush diluted EkoBond (3:1, EB:W) into fabric

Let it dry

Iron down any edges/tapes/bubbles

Iron glue joints at 135 deg C

Use damp paper towel to cover unused EkoBond

EkoFill

EkoFill (1K filler, smoothing and UV protection)

1.3mm 3M AccuSpray nozzle green (1.2-1.4mm)

1.6 bar at 3M gun regulator (when triggered, 8 and 4 bar at compressor/festo regulator)

200µm strainer, white/yellow

15-30°C application temperature

Surface prep

Application

Undiluted, stir before each use

3 fog cross coats (3x2 coats), perimeter first

➜ second part of cross coat as soon as dull looking

After each cross coat (after 45min) ➜ dry sand dull, wipe&blow clean

Sand off all the microfuss of the pinked edges

Use Scotch Brite around sensitive areas like rib stitching

Iron down (110°C) pinked edges, iron out defects like bubbles

➜ don't sand through filler coat

EkoPoly after 8h (24°C)

last sanding right before (<10 days) top coating

EkoPrime

EkoPrime (1K primer, interior, fabric)

Stir (1K)

Strain (190 micron)

Spray

1.8mm nozzle (high build, undiluted)

1.2-1.4mm nozzle (10% diluted with distilled water)

8-10 psi

Temp: 15-30*C (60-85*F)

Fog coat at ~28cm distance

Wet coat at ~16cm distance (after fog coat is tacky)

EkoPoly/EkoCrylic after 4h (24°C)

EkoPoxy

EkoPoxy (2K primer, exterior, metal, composites)

1.6mm 3M AccuSpray nozzle (violett), 10 psi

200µm strainer

15-30°C application temperature

Surface prep for AL see EkoEtch

Mix

A:catalyst:water @ 200:36:26

Mix A with C

Wait 5min

Mix in water

Wait 5min

Check viscosity (21-23s #4 Ford cup)

Pot life: 4h (24°C)

Spray

1 fog cross coat, ~ 23cm distance

(let get tacky in between 5-10min)

EkoCrylic after 4h (24°C)

EkoPoly / EkoCrylic

EkoPoly (topcoat flexible, fabric) & EkoCrylic (topcoat harder, metal, composites), Flattner

1.3mm 3M AccuSpray nozzle green (1.2-1.4mm)

1.3 bar at 3M gun regulator (when triggered, 8 and 4 bar at compressor/festo regulator)

125µm strainer, blue

15-30°C application temperature

>18°C drying temperature (12h)

Surface prep

So when:

Previous layer is primer or filler

Previous layer has fully dried

Previous layer has imperfections, runs

Clean (lint-free towel, EkoClean)

Scuff until dull

Blow & tack-wipe

Clean (lint-free towel, IPA)

mix

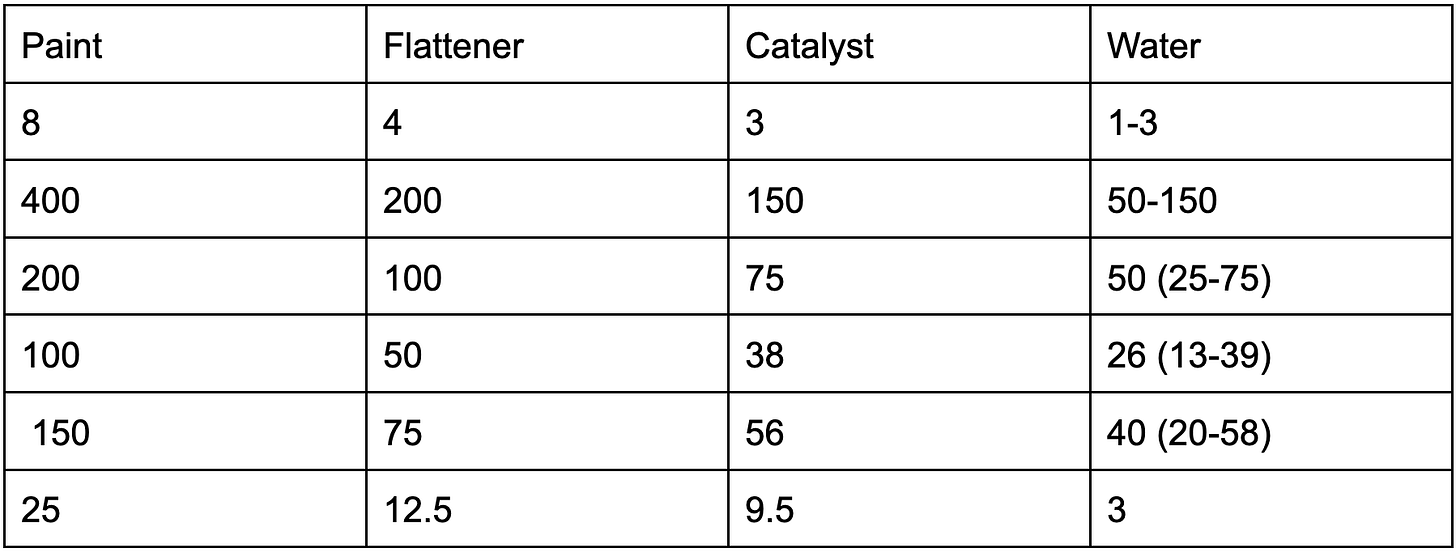

A:flat:catalyst:water @ 8:4:3:1-3 for flat paint (A:catalyst:water @ 4:1:1 otherwise)

Mix A (eg. 400g) with flattener (eg. 200g) - do it well!

Mix A/F (eg. 600g) with Catalyst (eg. 150g)

Wait 5min

Mix in water (as needed, eg. ~75g)

Wait 5min

Check viscosity (22-24s #4 Ford cup, fyi 17s for water)

Pot life: 3-4h

Spray

Tack coat

Wait until tacky (5-10min)

~4 fog coats, ~28cm distance (let get tacky in between 5-10min)

not for matte finish (wet coat at ~16cm distance after fog coat is tacky)

Time to dust free: 5h

Time to repaint/trims/masking tape: 24h

Thx Rick. This helps getting through the long hours in the shop ;)

Great workmanship Stefan, you are going to have one beautiful airplane when you are finished.