My usual strategy is to get started on a small piece, make sure I am happy with the results, then serialize any repetitive tasks. The tail feathers are a natural starting point for getting up to speed with the fabric covering process. Seeing how much the fabric can be manipulated also helps with strategizing the fuselage covering sequence. That being said, if you are tight on fabric, you might want to consider cutting out the large pieces first to reduce material waste.

To gain a good understanding of a new subject, I usually write my own summary and excerpts. This allows me to discard all the disclaimers, legal speak, and details that are irrelevant to my use case. Stewart’s starting point is their library. It has a solid collection of documents and videos. My overview of the Stewart System is in this Substack and might be a helpful starting point.

I enjoyed the covering. The heat-activated glue is actually quite nice to work with. And seeing the XHawk with skin for the first time is a strong reminder that this bird will be leaving the shop, and we will be flying into the sunset at some point.

Covering Speed Run

Preparation

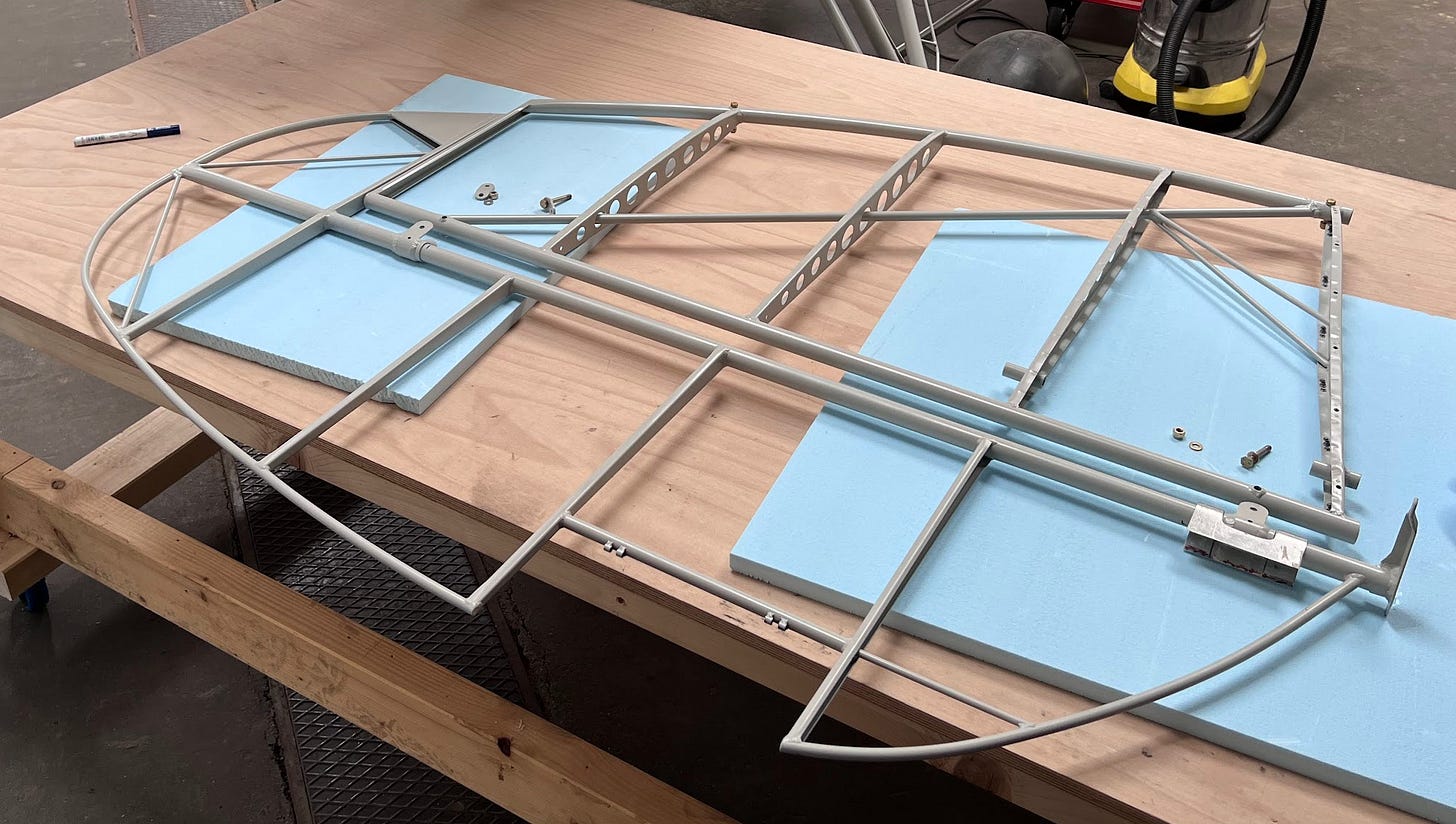

The stabilizers and control surfaces require some preparation. I fully installed them on the fuselage and made sure the internal trim tab controls work. Also the counterweight should balance the elevator in anticipation of the added weight of the painted fabric.

I also gave it some though on how to attach the horizontal stabilizer fairings. Some builders use metal screws. I prefer nutplates, so I made sure I have them in place on the root rib before covering. The fairings are typically attached only on this side and terminate on the fuselage side with rubber channels.

The kit comes with aluminum hinge frames. They provide a defined termination for the fabric around the hinges. To make them lay flat on the chromoly tube they need to be trimmed to clear the weld spots. Ideally they are bent slightly open so they press up and only the fabric tension holds them down planar to the surface. If they are too flat, ironing on the fabric gets tricky.

The bottom rudder hinge is not compatible with the aluminum hinge frames. Some builders weld a small piece of chromoly tube in place. Others shape some wood. I epoxied a piece of fuel tube in place.

Fabric Covering

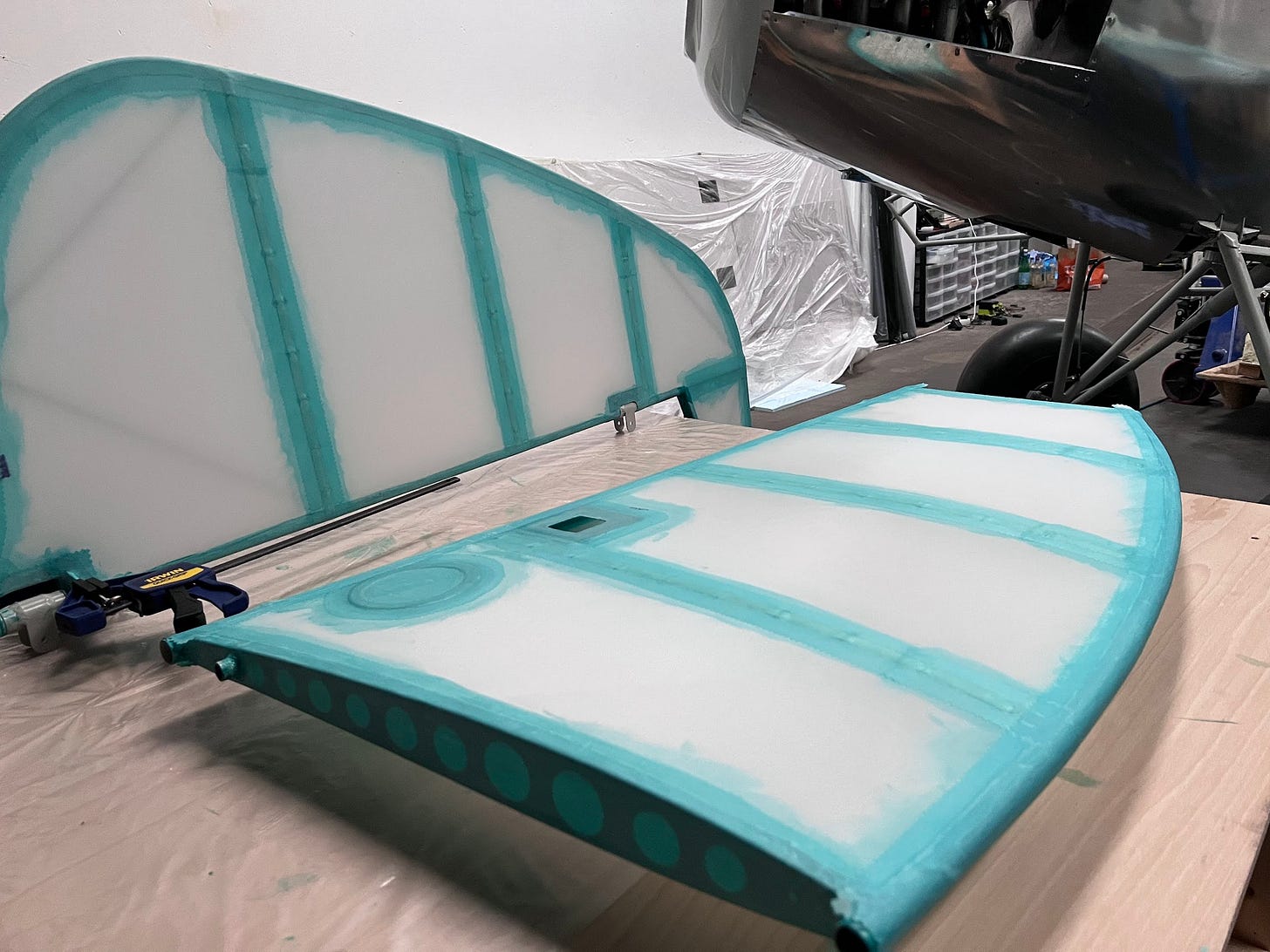

I used the two piece blanket technique for all parts but the trim tabs. This means that one side (typically bottom) is fully attached first. Then the second side is attached with an overlap around the perimeter.

Anti-chafe tape is typically run along the ribs. I applied it exactly in place of the rib stitching. Two more grams saved ;)

If you plan ahead you can place the aluminum frame for the trim tab service ports on the inside of the fabric. I didn’t. To properly fold the fabric to the inside I invented this aluminum shoe. Not only did I use it here but in many places of the fuselage, most importantly on the window frames and tail service ports. I find it essential, not sure how I would have done some of the intricate details.

The second blanket goes on with a 1” overlap. Depending on the tube diameter this requirement makes the fabric end at different distances from the edge. In any case, the overlap should still be narrow enough so the edge finishing tape can cover it.

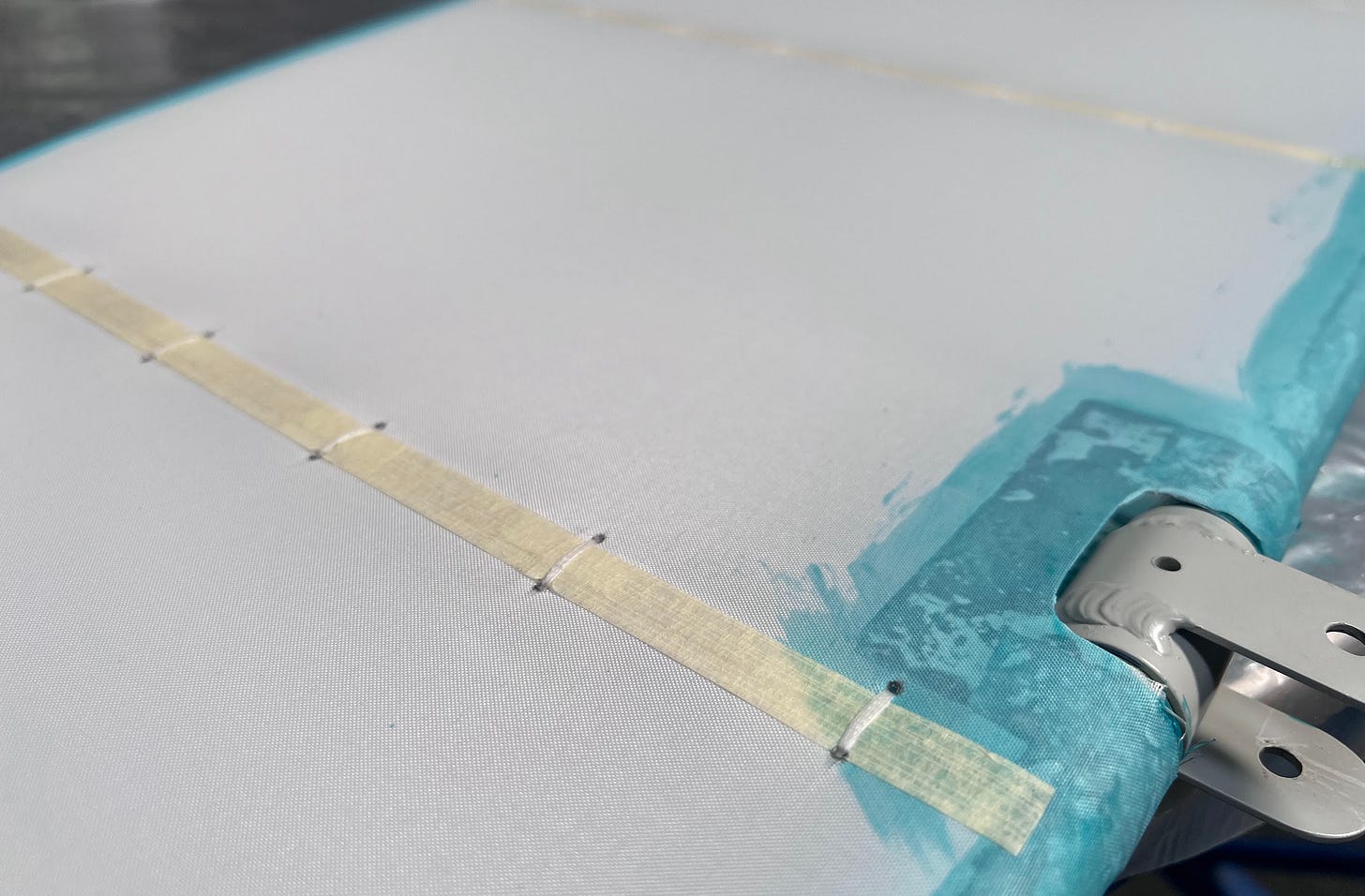

The rib stitching goes over the reinforcement tape. While this tape has strong tensile strength it does not adhere strongly to the fabric. The iron on low heat helps make it stick better.

To prevent the fabric from ballooning it is rib-stitched with a hidden modified Seine knot. I based the spacing on the AMT manual and made it less than 63mm (2.5”) and less than 38mm (1.5”) from the edge.

Finishing tapes go over all areas that need reinforcement. This specifically includes the ribs and the perimeter. Some planning on how they overlap is in order. For example, the rib tapes should go on before the edge tapes.

Clearance around the trim tabs is tight. If you overlap the fabric a lot around the corners the tabs won’t fit anymore or look wonky. They look fine by themselves, but once attached the gap appears very inconsistent. I had to sand some areas and re-apply a final layer of edge tape.

Final steps in the covering process are sealing the fabric (1:3 Ekobond to distilled water) and applying the first cross coat of EkoFill. If you continue straight to painting, it makes sense to do this already in the paint booth with a spray gun. If you put the tail feathers on hold, the first layer can be applied by foam brush. This allows you to deal with the booth setup later. This might entail a bit more sanding but I didn’t find that any brush strokes showed through the topcoat.